A path to higher as-built ductility in printable aluminum alloys

Monica Cooney

Sep 3, 2025

Most aluminum alloys made through additive manufacturing (AM) have very limited as-built ductility, which may lead to adoption of more expensive, heavier alternative materials in applications such as automotive and aerospace parts. Limited ductility in AM alloys can originate from specific AM processing defects or microstructural features. With all efforts in optimization of processing defects, still the microstructural effects have limited the as-built ductility of high strength Al alloys.

Researchers in the materials science and engineering department at Carnegie Mellon University have developed a new class of aluminum alloy (Al-Ni-Er-Zr) with an optimized composition that enhances as-built ductility from from 0.9% to 19%, while minimizing the effects on the alloy’s strength. Their recently published paper in npj Advanced Manufacturing shares the findings from the calculation of phase diagrams (CALPHAD)-based integrated computational materials engineering (ICME) simulations and the validation of the results.

Through experimental characterization, the research team systematically studied the embrittlement phases of existing alloys with low ductility and high strength in order to understand what causes them to break so quickly.

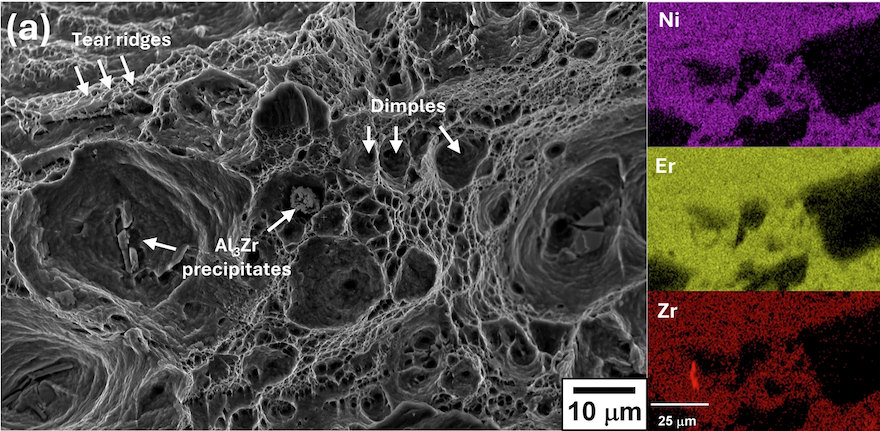

The fracture surface of the designed high-ductility alloy as shown through SEM characterization. Compared to the fractography of the benchmark alloy, the designed alloy exhibits a greater number and larger size of dimples.

“Once we found the origin of the fracture, we were able to perform a simulation to understand how we can optimize the elements in a way that maximized strength and improved ductility,” said assistant professor Mohadeseh Taheri-Mousavi, who supported this research along with her current doctoral student Zhaoxuan Ge.

High as-built ductility is important for those manufacturing techniques in which post heat treatment of prints are challenging, such as welding. These processes are key to structural integrity in applications such as automobiles and aircraft.

“With improved ductility, strength, and temperature tolerance, aluminum alloys could replace heavier, more expensive titanium and nickel alloys and steels,” said Taheri-Mousavi.

As-built ductility, which does not include any subsequent post-processing techniques, is important for larger scale printing in AM, because a material cannot tolerate the residual stress encountered during printing if it has low ductility. As such, the new formula has potential to be used on larger components of automotive and aerospace vehicle parts.

Additional contributors to this work included researchers from Max Planck Institute for Sustainable Materials, Warsaw University of Technology, Amazemet Sp. z o.o. [Ltd], and Massachusetts Institute of Technology. This research was made possible through support from the Naval Nuclear Laboratory (Award No. 1043353).