A new approach to classifying materials development

Monica Cooney

Aug 28, 2025

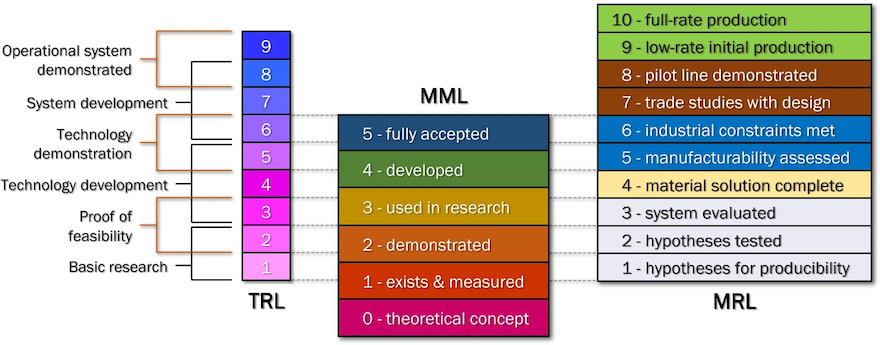

The way in which materials are developed encompasses many complex processes, often starting with computational simulations long before the formulas are synthesized, scaled, and tested. While frameworks have been established for systemizing the advancement of technologies and manufacturing, such as Technology Readiness Level (TRL) and Manufacturing Readiness Level (MRL), there has not been a parallel framework that speaks specifically to materials discovery.

A recent publication led by materials science and engineering professor Anthony Rollett proposes a benchmarking tool of Materials Maturity Levels (MML) that will enable researchers to advance their work from discovery through synthesis, to scale-up, and incorporation into systems through defining a set of qualifications.

This framework will be useful as materials developers work with users to understand and evaluate the process.

Anthony Rollett, U.S. Steel Professor of Metallurgical Engineering and Materials Science and University Professor, Carnegie Mellon University

“Many factors are taken into account when considering the viability of a new material,” said Rollett. “This framework will be useful as materials developers work with users to understand and evaluate the process.”

The MML sequence ranges from 0-5, with parameters as follows:

- 0 - Theoretical Concept: Material with interesting property(-ies) discovered via theory and/or numerical simulation

- 1 - Material Exists: Material synthesized at the laboratory scale and is stable

- 2 - Material Property Demonstrated: Large enough quantities have been produced and tested to establish potential scale-up

- 3 - Laboratory Use of Material Validated: Materials capability is verified and validated for limited application cases

- 4 - Industry Use of Material Validated: Material used by industry for a specific application and scale-up demonstrated

- 5 - Material Fully Accepted: Material is used for more than one application, validated with publicly available test data

Because TRL and MRL are well-established metrics and materials maturity is related to both manufacturability and technological applications, the authors also linked their framework to these tools to align various stages of readiness/maturity.

“Since materials discovery encompasses both new applications and improvements to existing formulations, MML will be useful to a wide audience of those involved in materials development and the adoption of new materials,” Rollett noted.

The end goal is that the MML will be a tool which can accelerate materials maturity. As materials developers work together, a co-design process through which modifications to existing applications can be set in motion to make the best use of newly identified properties.

The MRL scale is well aligned with the TRL scale so, given that a fully mature material needs to be manufacturable at the appropriate scale, a material must have been fully assessed for manufacturing along with any industrial constraints before it can be considered to be fully mature.

“Since materials discovery encompasses both new applications and improvements to existing formulations, MML will be useful to a wide audience of those involved in materials development and the adoption of new materials,” Rollett noted.

The end goal is that the MML will be a tool which can accelerate materials maturity. As materials developers work together, a co-design process through which modifications to existing applications can be set in motion to make the best use of newly identified properties.

Additional contributions to this research were made by researchers at the Institute for Defense Analyses (IDA), California Institute of Technology, the University of Maryland and the Department of Defense.